< Plastics & Rubber > Projects > Products > Programs > Professional > Process > Proposals > Progress

Get A Quote in Cards

FILM & SHEET EXTRUSION LINES

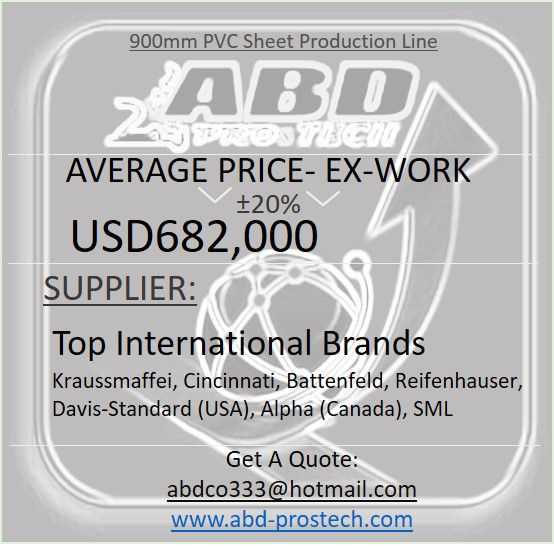

900mm PVC SHEET EXTRUSION LINE

Wide (mm)

850 mm (max)

Thickness (mm)

0.20 - 2.00

Material & Layers

PVC - 1 Layer

Productivity

250 Kgs/hr

Main Items

Auto Feeding & Drying System (1 Set), Main Double Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Gear Pump (1 Set), Flat-Slot-T Die (1 Set), Extrusion Die Adapter (1 Set), Three Roll Calendering Machine (1 Set), Roll Temperature Adjustment (1 Set), Cooling& Transfer Bridge (1 Set), Edge Trim Unit (1 Set), Edge Winder (1 Set), Two Roll Take Off (1 Set), Winder (1 Set). Total Power: 110 Kw.

1300mm PVC SHEET EXTRUSION LINE

Wide (mm)

1300 mm (max)

Thickness (mm)

0.20 - 2.00

Material & Layers

PVC - 1 Layer

Productivity

350 Kgs/hr

Main Items

Auto Feeding & Drying System (1 Set), Main Double Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Gear Pump (1 Set), Flat-Slot-T Die (1 Set), Extrusion Die Adapter (1 Set), Three Roll Calendering Machine (1 Set), Roll Temperature Adjustment (1 Set), Cooling& Transfer Bridge (1 Set), Edge Trim Unit (1 Set), Edge Winder (1 Set), Two Roll Take Off (1 Set), Winder (1 Set). Total Power: 160 Kw.

900mm PS SHEET EXTRUSION LINE

Wide (mm)

900 mm (max)

Thickness (mm)

0.20 - 2.00

Material & Layers

PS - 1 Layer

Productivity

300 Kgs/hr

Main Items

Auto Feeding & Drying System (1 Set), Main Single Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Gear Pump (1 Set), Flat-Slot-T Die (1 Set), Extrusion Die Adapter (1 Set), Three Roll Calendering Machine (1 Set), Roll Temperature Adjustment (1 Set), Cooling& Transfer Bridge (1 Set), Edge Trim Unit (1 Set), Edge Winder (1 Set), Two Roll Take Off (1 Set), Two Station Winder (1 Set). Total Power: 180 Kw.

900mm PET SHEET EXTRUSION LINE

Wide (mm)

900 mm (max)

Thickness (mm)

0.30 - 1.00

Material & Layers

PET - 1 Layer

Productivity

300 Kgs/hr

Main Items

Auto Feeding & Drying System (1 Set), Crystallization Dryer (1 Set), Main Single Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Gear Pump (1 Set), Flat-Slot-T Die (1 Set), Extrusion Die Adapter (1 Set), Three Roll Calendering Machine (1 Set), Roll Temperature Adjustment (1 Set), Cooling& Transfer Bridge (1 Set), Edge Trim Unit (1 Set), Edge Winder (1 Set), Two Roll Take Off (1 Set), Two Station Winder (1 Set). Total Power: 190 Kw.

1300mm PP SHEET EXTRUSION LINE

Wide (mm)

1300 mm (max)

Thickness (mm)

0.30 - 1.00

Material & Layers

PP - 1 Layer

Productivity

300 Kgs/hr

Main Items

Auto Feeding & Drying System (1 Set), Main Single Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Gear Pump (1 Set), Flat-Slot-T Die (1 Set), Extrusion Die Adapter (1 Set), Three Roll Calendering Machine (1 Set), Roll Temperature Adjustment (1 Set), Cooling& Transfer Bridge (1 Set), Edge Trim Unit (1 Set), Edge Winder (1 Set), Two Roll Take Off (1 Set), Winder (1 Set). Total Power: 160 Kw.

1600mm PP CASTING FILM EXTRUSION LINE

Wide (mm)

1600 mm (max)

Thickness (mm)

0.02 - 1.00

Material & Layers

PP - 1 Layer

Productivity

500 Kgs/hr

Main Items

Auto Feeding & Dosing System (1 Set), Main Single Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Metering Pump (1 Set), Flat-Slot-T Die (1 Set), Extrusion Die Adapter (1 Set), Chilled Casting Unit (1 Set), Three Roll Calendering Machine (1 Set), Roll Temperature Adjustment (1 Set), Cooling& Transfer Bridge (1 Set), Edge Trim Unit (1 Set), X-Ray Thickness Control Device (1 Set), Edge Winder (1 Set), Take Off Equipment (1 Set), Tension Control Winder (1 Set). Total Power: 220 Kw.

1500mm PE STRETCH FILM EXTRUSION LINE

Wide (mm)

1500 mm (max)

Thickness (mm)

0.02 - 1.00

Material & Layers

PE (PP)+CaCo3 - 1 Layer

Productivity

300 Kgs/hr

Main Items

Auto Feeding & Dosing System (1 Set), Main Single Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Metering Pump (1 Set), Feedblock and Flat Die (1 Set), Extrusion Die Adapter (1 Set), Casting Station (1 Set), Air Knife / Softbox (1 Set), X-Ray Thickness Control Device (1 Set), Machine Direction Orientation (MDO) (1 Set), Corona Treatment Unit (1 Set), Trim Handling System (1 Set), Winder (1 Set). Total Power: 220 Kw.

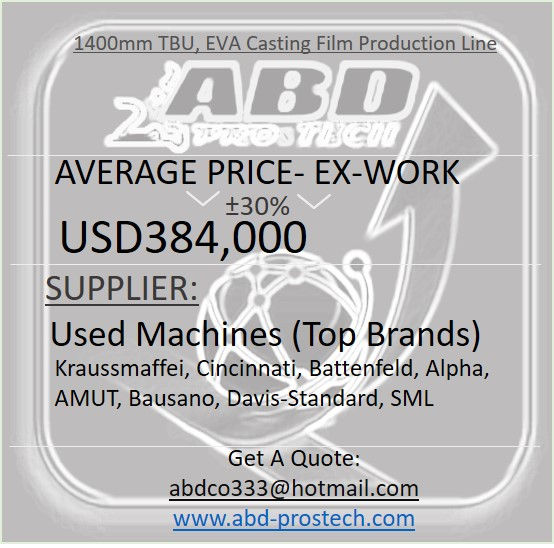

1400mm TBU, EVA CASTING FILM EXTRUSION LINE

Wide (mm)

1500 mm (max)

Thickness (mm)

0.05 - 0.20

Material & Layers

EVA, TBU - 1 Layer

Productivity

200 Kgs/hr

Main Items

Auto Feeding & Dosing System (1 Set), Main Single Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Metering Pump (1 Set), Flat Die (1 Set), Hanger Mold (1 Set), Chilled Casting Unit (1 Set), Roll Calendering Machine (1 Set), Longitudinal Stretching Machine (1 Set), Cooling& Setting Device (1 Set), Transverse Stretching Machine (1 Set), Slitting Device (1 Set), Take Off Equipment (1 Set), Tension Control Winder (1 Set). Total Power: 190 Kw.

BOPP (BOPET) FILM EXTRUSION LINE

Wide (mm)

3000 mm (max)

Thickness (mm)

0.02 - 0.20

Material & Layers

PP, PE, PET - 3 Layer

Productivity

600 Kgs/hr

Main Items

Auto Feeding & Dosing System (1 Set), Main Single Screw Extruder (1 Set), Co- Single Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Metering Pump (1 Set), Feedblock and C-Extrusion Flat Die (1 Set), Extrusion Die Adapter (1 Set), Casting Station (1 Set), Air Knife / Softbox (1 Set), X-Ray Thickness Control Device (1 Set), Machine Direction Orientation (MDO) (1 Set), Corona Treatment Unit (1 Set), Trim Handling System (1 Set), Winder (1 Set). Total Power: 260 Kw.

PP/PS BARRIER THERMOFORMING EXTRUSION LINE

Wide (mm)

2100 mm (max)

Thickness (mm)

0.02 - 1.00

Material & Layers

PP, PS - 3 Layer

Productivity

1000 Kgs/hr

Main Items

Auto Feeding & Dosing System (1 Set), Main Single Screw Extruder (1 Set), Co- Single Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Metering Pump (1 Set), Feedblock and C-Extrusion Flat Die (1 Set), Extrusion Die Adapter (1 Set), Casting Station (1 Set), Air Knife / Softbox (1 Set), X-Ray Thickness Control Device (1 Set), Machine Direction Orientation (MDO) (1 Set), Corona Treatment Unit (1 Set), Trim Handling System (1 Set), Winder (1 Set). Total Power: 300 Kw.

1400mm PE STONE PAPER FILM EXTRUSION LINE

Wide (mm)

1400 mm (max)

Thickness (mm)

0.15 - 0.40

Material & Layers

PE (PP)+CaCo3 - 1 Layer

Productivity

550 Kgs/hr

Main Items

Auto Feeding & Dosing System (1 Set), Main Single Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Hydraulic Screen Changer (1 Set), Melting Pump (1 Set), T-Die (1 Set), Three Roll Calender (1 Set), Temperature Control System (1 Set), Preheating Rollers Group (1 Set), Cooling and Back Fire System (1 Set), Cooling System and Edge Cut (1 Set), Machine Direction Orientation (MDO) (1 Set), Thickness Gauge (1 Set), (1 Set), Rotational Double Position Winder (1 Set). Total Power: 290 Kw.

1600mm PP MELT BLOWN FABRIC PRODUCTION LINE

Wide (mm)

Fiber D (um) / GSM

1600 mm (max)

2 - 5 / 15 - 80

Material & Layers

PP+4% Masterbatch - 1 Layer

Productivity

100 Kgs/hr

Main Items

Auto Resin Dryer & Transfer Machine (1 Set), Main Single Screw Extruder (1 Set), Automatic Control Panel (1 Unit), Screen Changer (1 Set), Main Pump Unit (1 Set), Heating System for Hot Air (1 Set), Melt Blown Box ,(T-Die, Distribution, Spinneret) (1 Set), Collection Device (Conveyor, Drum) (1 Set) Winder (1 Set), High Voltage Electrostatic Device.

----------------

Technic : Melt Blown, Line Speed: 10- 300 M/min, Total Power: 300 Kw.