من مصر إلى �كل مكان، ومن كل مكان إلى مصر

PRODUCTION MACHINERY & EQUIPMENT

OUR TASK

We supply, install, commissioning and manage Machinery&Extrusion Lines which used mainly in the area of agricultural water supply system, drain, buried drainage, gas transport, architectural water supply system, pavement and protection of cables and many kinds of applications.

Our Principals have been the best international suppliers from USA, Germany, Italy, China, Taiwan, South Korea with various levels of technologies based on best value to price ratio.

PLASTICS PIPE PRODUCTION EXTRUSION LINES& EQUIPMENT

TYPES& RANGE

-

PVC Pipe Extrusion Line Till 1000mm

-

PVC Pipe Extrusion Line & Belling Machine

HDPE Large Pipe Extrusion Line

-

PVC Hollow Wall Pipe Extrusion Line

-

PE, PP, ABS Pipe Extrusion Line Till 2400mm

-

PPR, PEX, PE-RT, WTPP-R Pipe Extrusion Line

-

WTPP-R Pipe Extrusion Line

PPR Multi Layers Pipe

Corrugated Pipe Tools (Corrugator)

-

PE Multi-Layer Pipe

-

High Pressure RTP Twisted Pipe Extrusion Line

-

Big Bore Steel 3-Layer PE Coating

-

It overcomes the defects of PP-R pipe common type such as high expansion coefficient, bad anti-tardily variation, very easy to deform. Inner layer of pipe is the common pipe extruded, after it is coated with aluminum foil, then coated by a PP-R out layer, the foil layer is stick to plastic layer using hot-melt glue.

-

PVC, PE Double Wall Corrugated Pipe Extrusion Line

-

PVC, PE, PP Single Wall Corrugated Pipe Extrusion line

-

PE Multi-Layer Pipe Extrusion Line

-

PVC, PE Double Wall Corrugated Pipe Extrusion Line

-

PVC, PE, PP Single Wall Corrugated Pipe Extrusion line

-

PE Multi-Layer Pipe Extrusion Line

-

This production line is applicable for producing PE/PE, PE/glass fiber/PE, PE/PP, PE/PVC etc. composite pipes for the use of water supplying, drain, especially the composite pipes such as PE/GLASS FIBER/PE can endure pressure 200kg/cm2. It is the best choice substitute for steel- plastic composite pipes

-

High Pressure RTP Twisted Pipe Extrusion Line

-

Big Bore Steel 3-Layer PE Coating Extrusion Line

PLASTICS SHEET PRODUCTION EXTRUSION LINES& EQUIPMENT

-

PVC clear, PVC color Sheet Extrusion Line

-

PVC Free Foamed Sheet Extrusion Line

-

PS, HIPS, PC Sheet Extrusion Line

-

PP, HD/ LD-PE Sheet Extrusion Line

-

ABS, PMMA Sheet Extrusion Line

-

EPE, Cross-linked PE Foam Sheet Extrusion Line

-

Aluminum & Plastic Laminating Sheet Extrusion Line

-

PP& CaCo3 Sheet Extrusion Line

-

PP, HIPS, PE, PET, ABS, EVA, EVAOH Single, Multi-Layer Sheet Co-Extrusion Line

-

PE Multi-Layer Air-Bubble Sheet Extrusion Line

TYPES& RANGE

PLASTICS PROFILE PRODUCTION EXTRUSION LINES& EQUIPMENT

TYPES& RANGE

-

PVC, PC, PP, PE Window Profile Extrusion Line

-

PC, PP, PE Hollow Profile Board Extrusion Line

-

Foaming Profile Extrusion Line

-

Wide Door Profile Extrusion Line

PLASTIC&WOOD COMPOUND (WPC) EXTRUSION LINE& EQUIPMENT

-

In many process for Wood Plastic Composite (WPC) production, natural fiber can be mixed with polymer from 30%-80%. Therefore, selected the natural fiber (sawmill, chipboard, sawdust, rice husk,…) is quit important. All the natural fiber needs to be pulverized into around 40 mesh- 120 mesh particle size.

-

Dosing / Mixing and Special Compounding Unit

-

Dosing: The optimal formulation (by weight)

-

Polymer: PVC 30%-50%

-

HDPE/PP 30%-50%

-

Natural Fiber: wood fiber/sawmill/rice husk ... 30%-80%

-

Additive: Depend the formulation 0.5% - 5% or more

-

Mixing and Compounding: for mixing natural fiber/resin/ additives

TYPES& RANGE

-

PVC, PC, PP& Wood Profile Extrusion Line

-

PVC, PC, PE, PP& Wood Board Extrusion Line

-

Pulverizing System

PLATE PRODUCTION EXTRUSION LINE& EQUIPMENT

TYPES& RANGE

-

PVC Free Foaming Plate Extrusion Line

-

PVC Skinning Foaming Plate Extrusion Line

-

CPP, CPE, EVA Mono, Multi-Layers

-

Aluminum & PE Compound Plate Extrusion Line

-

XPS, XPE, IXPE Foam Plate Extrusion Line

-

PVC Floor Wide Board Extrusion Line

-

PC, PVC Wave and Corrugated Board Extrusion Line

XPS Heat Insulation Foamed Plate Extrusion Line

XPS extrusion plates are widely used in heating insulation field such as cold storage, food storage, airport running way, square and so on.

This line consists of material mixing system, extruding system, downstream equipment, pelletizer, foam agent injection system, etc.

The products made by this line are widely used in industries such as food, packing, furnishing, engineering temperature proof, engineering waterproof, pipe temperature proof, and packing of electrical products.etc. developed totally four types, namely 65-90, 90-120, 100-130, 120-150,

FILM PRODUCTION EXTRUSION LINE& EQUIPMENT

Thanks to the wide scope of possible applications, thermoforming sheets made of high-quality raw materials such as polystyrene, polypropylene or polyester have become an integral part of everyday life. Everybody comes across thermoforming sheet products regularly on the shelves of the supermarket. Whether in the form of yoghurt or ice cream cups, margarine or milk containers, or as trays for TV or microwave meals or as blister packs, thermoforming sheets have become indispensable for transport and protection of foodstuffs and drinks. This is not the only place where we daily meet polished sheet products - they also abound in the office and especially in our cars. The automotive industry in particular uses thermoforming sheet with smooth or embossed surfaces for high-quality inner panelling.

TYPES& RANGE

-

LDPE, HDPE, PP Casting Film Extrusion Line

-

ASA PETG HIPS cast film extrusion line

-

PE/PP Stretching Film Extrusion Line

COMPOUND& PELLETIZING EXTRUSION LINE& EQUIPMENT

TYPES& RANGE

-

PP, PA, PIST, ABS, PPS, PC, PET, PMMA Co-rotating Parallel Extrusion Granule Extrusion Line

-

PET, PP, PA6, PE, ABS, PVC Pelletizing Extrusion Line

-

PET Crystallization& Drying System

-

Alter Nature and Master Batch Extrusion Line

-

Co-rotating Parallel Extrusion Granule Extrusion Line

-

High Efficient Vented Single Screw Granule Extrusion Line

MIXING& WEIGHING SYSTEM& EQUIPMENT

-

PVC & Filler& Additives Mixing System

-

High Speed Horizontal Or Vertical Type

-

Computerized PLC Packing systems

-

Auto Dosing, Feeding and Conveying System

-

Gravimetric and Volumetric Mixing System

TYPES& RANGE

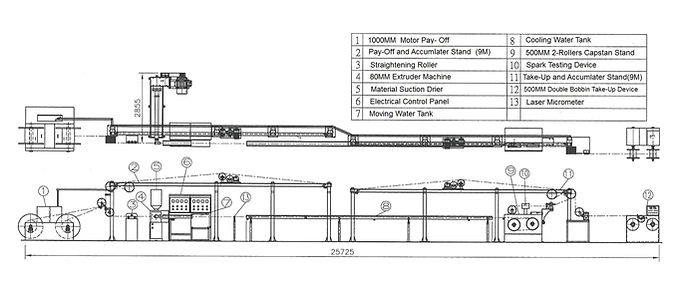

WIRE& CABLE SHEATHING EXTRUSION LINES

TYPES& RANGE

-

PVC, PE, PBT, PA, PTFE Wire& Cable Sheathing Extrusion Line

-

Light Optics, Fiber Light Optics Cable Sheathing Extrusion Line

-

Cross-linked Cable Sheathing Extrusion Line

-

Coaxial Foam Cable Sheathing Extrusion Line

EXTRUDERS

-

Single Screw Extruder for PE, PP

-

Conical Twin Screw Extruder

-

Parallel Twin Screw Extruder

-

Spinning Extruder

-

Rubber Extruder

-

Co-rotating Parallel Extruder

TYPES& RANGE

SCREW& BARREL SETS

-

Single Screw& Barrel Set for PE, PP

-

Conical Twin Screw& Barrel Sets

-

Parallel Twin Screw& Barrel Sets

-

Spinning Screw& Barrel Sets

-

Rubber Screw& Barrel Sets

-

Co-rotating Parallel Screw& Barrel Sets

TYPES& RANGE

DOWN STREAM EQUIPMENT

TYPES& RANGE

-

Vacuum Calibration Tank

-

Spray Cooling Tank

-

Caterpillars Haul Off

-

Planetary Saw

-

Calendar

-

Winder

-

Spinning Winder

-

Melting Pump

-

Belling Machines

-

Die Head& Tools

-

Accessories

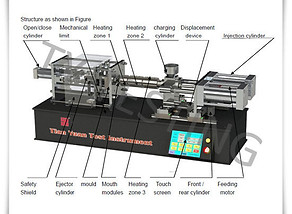

PLASTICS INJECTION MOLDING MACHINE

TYPES& RANGE

-

The ideal machine concept for every application innovative injection moulding machines from 280 kN to 55,000 kN clamping force, hydraulic, fully electric, horizontal and vertical solutions.

RUBBER INJECTION MOLDING MACHINE

TYPES& RANGE

-

• Machine for natural, synthetic, oil resistant, heat resistant and reclaimed rubber.

-

• Low bed structure with lower working platen high.

-

• PLC and HMI functional control as standard specification.

-

• Direct and indirect clamping structure.

-

• Specialized nozzle design to prevent material overflow.

-

• Specialized feeding device.

RUBBER PROCESSING MACHINERY

-

Rubber Internal Mixers

-

Intermeshing Rotor Type

-

Internal Mixer

-

Rubber Open Mill

-

Rubber Dispersion Mixers

-

Rubber Cracker

-

Mechanical Tire Curing Press

-

Hydraulic Tire Curing Press

-

Tire Retreading Press

-

Curing Oven

-

Tire Retreading Equipment

-

Tire Recycle Equipment

-

Rubber Slice Equipment

-

All Steel/Semi Steel Radial Tire

-

Multi-Blade Slitting Machine

-

Auto Cutting& Splicing Machine

TYPES& RANGE